Tools for the printed wiring board processing and How to use

The power tool is still convenient to process a large amount of substrate well though a manual tool can be used for the processing of printed wiring board (PCB,PWB). It introduces the usage of the small, desk-top ball board and the electric substrate cutter.

How to use of the small, desk-top drill (mini desk drill).

This is a small, desk-top desk drill of (HOZAN) that I am using It is (mini desk drill. )It is three belt multiplication changing type step changing the speed, and the motor is a commutator motor.

It is for the printed wiring board and the processing of plastic because it is small chiefly though metalworking can be never never done.

I am using it for various perforations of the substrate and cutting the copper foil of the substrate, etc.The main perforations such as resistance and capacitors installed in the substrate use a drill blade of Φ0.9mm sold by moon Electronic commerce in autumn. It seems not to have sold it any longer now.

Cutting the copper foil usually uses the retractable knife, and the globular rotary cutter of high-speed steel is installed and being used for this small, desk-top ball board by me though are a lot of users. The globular part is the one of the size of Φ1.5mm. It sells it also in the hundred-yen store. The [umaku] copper foil can be very cut by moving it with the printed wiring board in the hand.

If the diamond grindstone for the mini router is installed, the metal and the glass can be processed.

Please use safety glasses to prevent the cutting rubbish from catching one's eye as notes of the usage.

Please use the maintenance of the small, desk-top ball board after checking whether to find trouble in the cleaning without fail, and each part after it uses it. Please oil it if necessary. Moreover, please exchange it when sometimes checking and hurting because the belt is an articles of consumption.

The small, desk-top ball board:The main specification of [ho-zan] K-21.

- Main axis rotational speed-----2100/4500/6200 rpm (belt multiplication changing method)60Hz time

- Holing open ability-----Iron and non-iron 6.0mmφ

- Wick blur in main axis-----0.04mm(It doesn't contain the zipper. )

- [Chakkingu] diameter-----0.8〜6.0mmφ

- Voltage rating and frequency-----AC100V 50/60Hz

- Power consumption-----80W ratings time 15 minutes

- Externals size-----120(W) 350(H) 25(D) mm weight 4Kg.

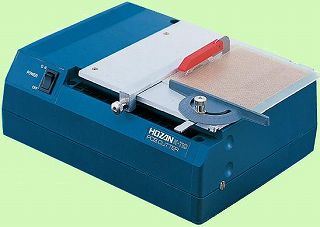

How to use of the electric PCB cutter.

It is the one that doesn't cut beautifully easily though I was using the money switching off saw for cutting the printed wiring board. Moreover, it took a lot of time in a manual tool to cutting a large amount of substrates.

Because the diamond cutter has been equipped normally with substrate cutter K-110 of [ho-zan] in this photograph, the ceramic substrate not to mention the glass epoxy board can be cut. Moreover, the cutting plane of the diamond cutter completely leaves neither [kaeri] nor Bali. It is possible to process it also to complex shape of the chamfering and the u-shaped, etc. with the diamond cutter.

After obtaining this substrate cutter, cutting the substrate uses this for me almost all. It is quite convenient. [Hokori] flies up if not working outside the house because the cutting rubbish that cuts the substrate is too detailed if it dares to say.

I also have not used this for other usages, and can use it to cut the board material such as the metal, plastic, and wood by exchanging the disk cutters.

The usage is not difficult at all. 、The substrate can ..same size.. be cut by using the guide well. Moreover, please use it for safety with the blade of the cutter covered.

PPlease use it as maintenance after checking whether to find trouble in the cleaning without fail, and each part after it uses it. Please oil it if necessary.

The PCB cutter:The main specification of [ho-zan] K-110.

- Rotational speed-----3500rpm

- Standard disk cutter-----Diamond cutter K-110-1

- Voltage rating and frequency-----AC100V 50/60Hz

- Power consumption------80W

- Ratings time-----15 minutes(At a continuous load. )

- Size of table-----160(W)×160(D)mm

- Externals size-----245(W)×100(H)× 185(D)mm

- Weight-----1.7kg